Sub Micron Placer

The solution for those processes that require high accuracy, high precision and high repeatability of positioning on tiny components with a powerful software tool.

POWER SOFTWARE TOOL

Nowadays, components are getting smaller and smaller down to the sub-micron level. Large number of components have to be integrated into a smaller package to increase the complexity and also the performance.

Greatech machines offer the solution for those processes that require high accuracy, high precision and high repeatability of positioning on tiny components with a powerful software tool. The software tool provides the feature of Error Mapping which further enhance the machine accuracy performance.

Greatech has been involved in the field of developing machines for years and this vast experience has contributed to the production of higher effectiveness and capabilities of machines. This results in a higher level of performance in machining operation.

The rapidly changing technology which has a positive effect on the performance of the machines also enable us to adapt to the changing to customers’ requirements.

MOTION CONTROL FOR

ACCURATE & REPEATABILITY POSITIONING

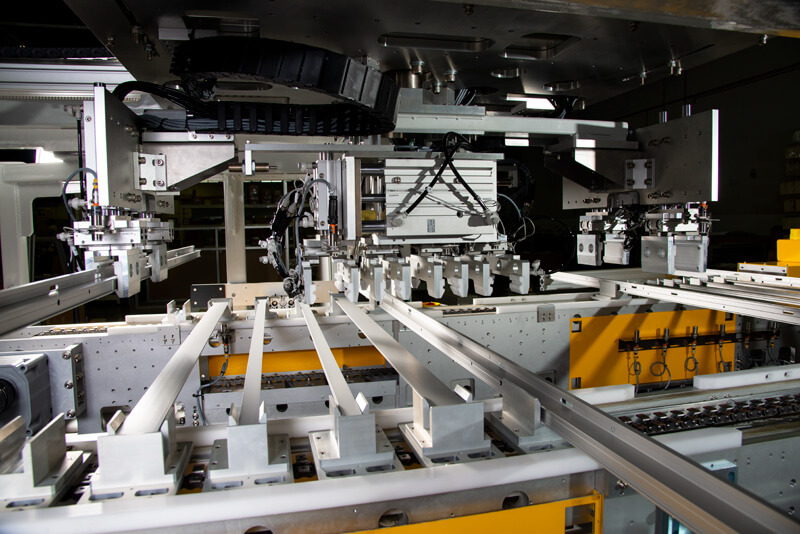

The first thing that comes to mind when designing a machine is the accuracy, repeatability and the precision of positioning. Motion control functions that employ the controlling of multi-axis are usually integrated in our machines. Ex. linear translation and rotational stages, long-travel gantries. Furthermore, the real-time controllers also implement a fast interpolation control function.

Task such as in line pick-and-place either is active or passive alignment are integrated in the machines, providing an accurate and precise positioning (down to sub-micron level and sub-arc second accuracy).

Lastly, all the motion controls are controlled by Greatech’s user-friendly, flexible programming software, Greatech’s Integration Platform.

CAPABILITIES

PASSIVE ALIGNMENT

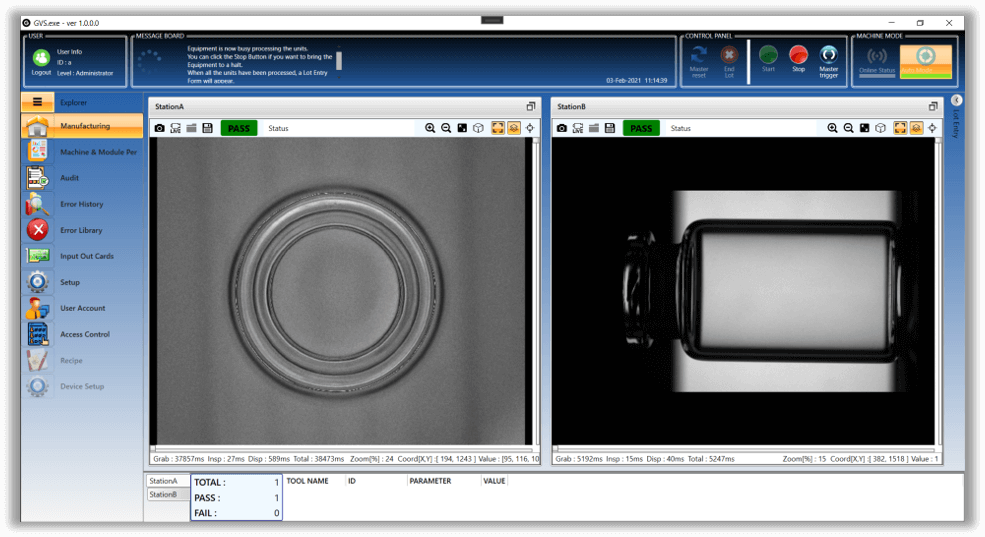

Passive alignment employs the usage of multiple camera system and advanced machine vision algorithms and maps all motion control via automated geometric calibration procedures.

Camera image space (pixel) can then be carefully calibrated to the actual motion space, up to the diffraction limit of the optical system, providing class-leading guidance, pre-alignment routines, and other advanced functionalities.

ACTIVE ALIGNMENT

Active alignment is additional step following passive alignment but it will be a bit slower. Active alignment is required when high accuracy application is needed i.e., sub-micron accuracy and high repeatability.

Optical parameter such as power is correlated with positioning in motion space. Nanometer-scale resolution can be achieved with piezo-driven stages, which utilize search trajectories that are pre-programed into the motion control firmware.

Application required passive and active alignment

- Fast active fiber alignment.

- Fiber pigtailing for edge-planer waveguide coupling.

- Single and arrayed fiber pigtailing for top-grating couple.

- Fiber-optic cable assembly.

- Laser bar stacking and alignment of collimating micro-optics.

- Compact camera module assembly.

EQUIPPED WITH

REVOLUTIONARY TECHNOLOGY

Key Technology for automation to realize improved process, product quality and system performance.

In this new era, data becomes important for monitoring, decision making and other various of reason.

Our strategic partnerships with laser suppliers and automation design gives the customer state-of-the-art laser processing tools in precision motion, advanced automation and material handling.