Responsibilities:

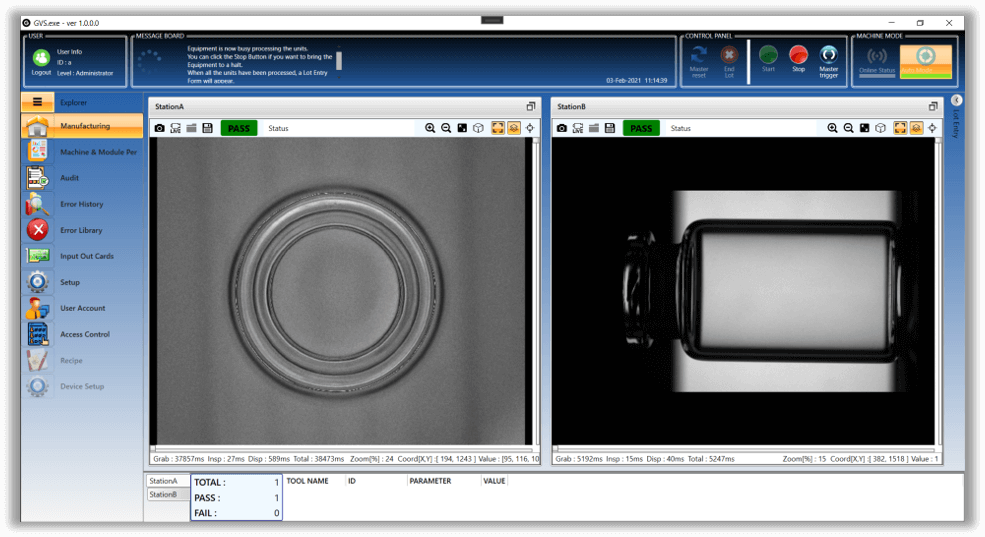

- Complete mechanical assembly / electrical assembly, installation and testing of equipment to time deadlines.

- Assemble and integrate a variety of mechanical and electrical assemblies.

- Obtain and verify kitted (pre-picket) detail parts and assemblies were issued correctly by comparing part numbers and quantities to drawing(s).

- Solve and resolve issues & feedback problems & solutions.

- Participate and cooperate within the team to complete overall task efficiently.

- Check work after completion of each operation in job and/or completed job to ensure assembly is complete per drawing, that there are no defects and that the work area is clean.

- Travel to customer sites and carry out installation, servicing work and training as scheduled.

- Report to facility department regarding any raising issues related to assembly plant.

- Monitor the area for the daily cleanliness of factory building and assembly plants 5S.

- Able to monitor sub contractual progress and guide them to finish up by the timeline.

- Update on the all parts received, pending and outstanding status and share with among the co-worker in order to keep installation on the track.

- Other duties and assignments as instructed by superiors from time to time.

- To comply with all requirements of ISO (inclusive of all standards approved by the Management) and to adhere to general safety practices, standard operating procedure, work instructions, policies and guidelines provided by the company.

Requirements:

- At least a Certificate Engineering (Electrical/Electronic), Engineering (Mechanical), Engineering (Mechatronic/Electromechanical) or equivalent experience.

- Minimum 2-3 year(s) of working experience in the related field is required for this position.

- Hands-on skill in mechanical or electrical assembly & Leadership.