Responsibilities:

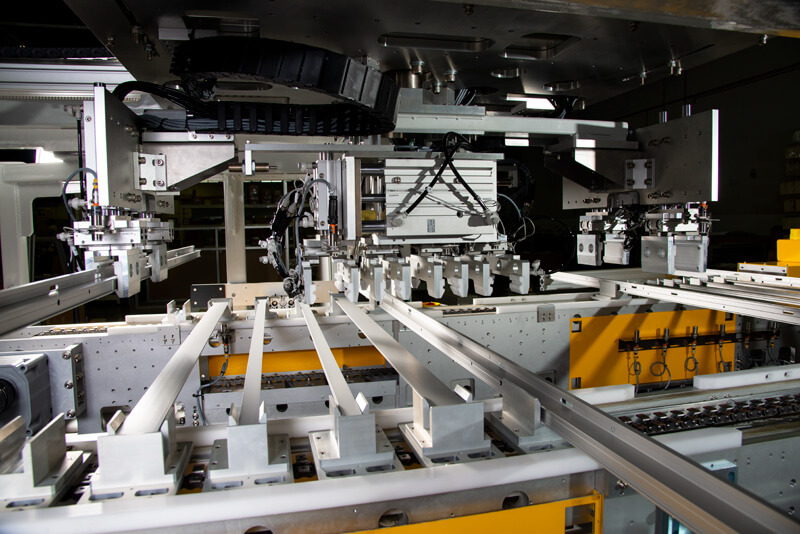

- Responsible for product design and development using 3D Cad software and other simulation tools.

- Plan and manage mechanical design schedule.

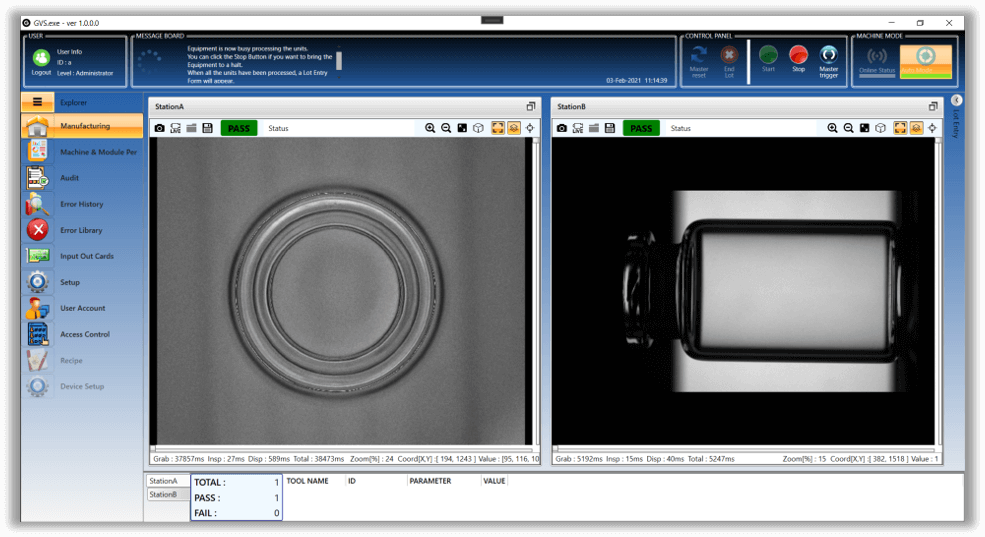

- Execute mechanical piece part design, process and tooling verification.

- Implement product and process improvement.

- Coordinate design phases, transfer and project scheduling.

- Checking of drawings and preparation of Bill of Materials (BOM).

- Translate customer’s requirement into design specification, evaluate design feasibility and provide technical expertise to meet customer’s request.

- Establishes design objectives for specific projects, perform detailed calculations and develop innovative and creative design for various difficult and complex project features.

- Coordinates and plans work for other drafters to complete a project assignment.

- On site support for mechanical related issues.

- Other duties and assignments as instructed by superiors from time to time.

Requirements:

- At least a Diploma, Advanced/Higher/Graduate Diploma, Bachelor’s Degree, Post Graduate Diploma, Professional Degree, Engineering (Mechanical), Engineering (Mechatronic/Electromechanical) or equivalent experience.

- 2 year(s) & above of working experience in designing automation equipment.

- Knowledge in SolidWorks, CAD/CAM software.

- Overseas business trip to set-up or buy-off machine.