01 Jan Penang: Promoting Green Manufacturing

This article first appeared in The Edge Malaysia Weekly on December 29, 2025 – January 4, 2026

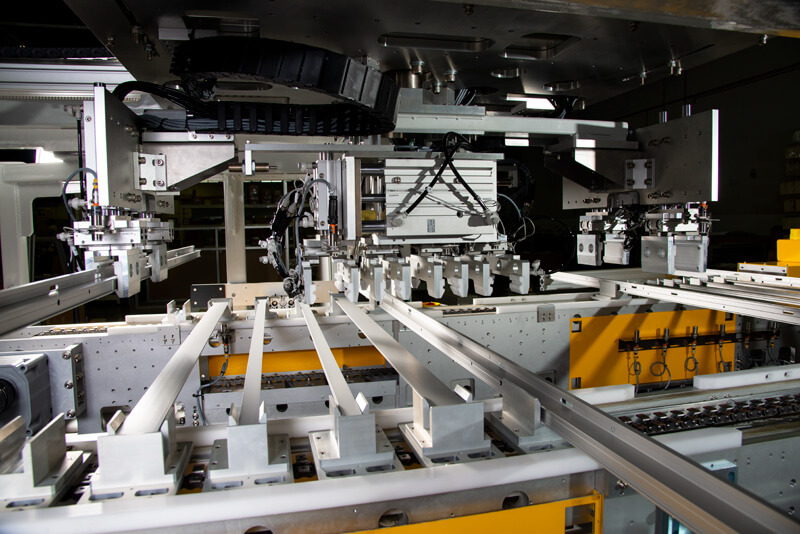

One of the participants of the Penang Green Council’s Penang Green Industry Programme (PGIP) is Greatech Technology Berhad (“Greatech”). The Bayan Lepas-based automation solutions provider has factories in Batu Kawan.

The PGIP aims to co-create solutions in ESG adoption, resource efficiency and green talent development with corporates, small and medium enterprises (SMEs) and government stakeholders.

Greatech joined the programme as part of its broarder commitment to embed sustainability into its operations and align with national and global ESG expectations, says Greatech Group chief financial officer Koay Lin Lin. “Our participation began when Penang introduced a structured roadmap for companies to operationalise environmental best practices,” she adds.

The company started by conducting an internal assessment of its energy usage, emissions profile, waste practices and existing controls, which formed its ESG baseline. “From there, we initiated improvements in energy efficiency (EE), invested in renewable energy (RE) capacity and strengthened our governance structures,” says Koay.

This is an important move for Greatech because its customers are in highly advanced and sustainability-driven sectors such as solar, electric vehicles and semiconductors, she adds. “So, their ESG expectations are high, especially in areas like emissions and responsible operations.”

Participation in an official state programme such as PGIP gives the company credibility and could help de-risk its supply chain. “It proves to our customers that our sustainability journey is regionally relevant and internationally recognised. It also strengthens our resilience and competitiveness, which is essential as ESG becomes a major decision factor in global supply chains,” she says.

The state government has introduced the Penang Energy Framework, which mandates sourcing of RE for new buildings and adoption of EE targets. Koay sees this as a validation of the company’s existing strategy of using RE and EE, which is seen as a cost-effective business decision.

“We do recognise, however, that this can be a significant cost burden, not just for new companies, but for many of our local SMEs… So, while we are on board, we believe it is critical that these regulations are supported by strong, accessible financial incentives like grants, tax exemptions or soft financing to ensure our entire industrial ecosystem, especially the SMEs, can meet these requirements without losing their competitiveness,” she says.

Greatech is taking a phased approach to support SME suppliers. The company is currently in the foundational phase of the programme, where the immediate focus is to establish its internal ESG baseline and map its supply chain to identify key SME partners and understand their shared risks.

“As we formalise this, our future roadmap, which we are actively developing, is built on partnership and not just compliance,” says Koay.

The roadmap will have three key parts, including the establishment of clear expectations via a supplier code of conduct and capacity building for SMEs, using national tools such as the i-ESG framework and the Simplified ESG Disclosure Guide (SEDG).

“Third, we aim to guide SMEs to available support, such as the Green Technology Financing Scheme and state-level programmes. This reduces the financial burden and accelerates their transition,” she says.

The challenges of the low-carbon transition are not limited to SMEs. According to Greatech’s 2024 annual report, total energy consumption had increased, even as its share of RE rose to 10%. This was due to a significant expansion in production capacity over the last year, observes Koay. “The primary challenge is managing this growth responsibly. Therefore, our core strategy has been to focus on energy intensity, not just absolute consumption.”

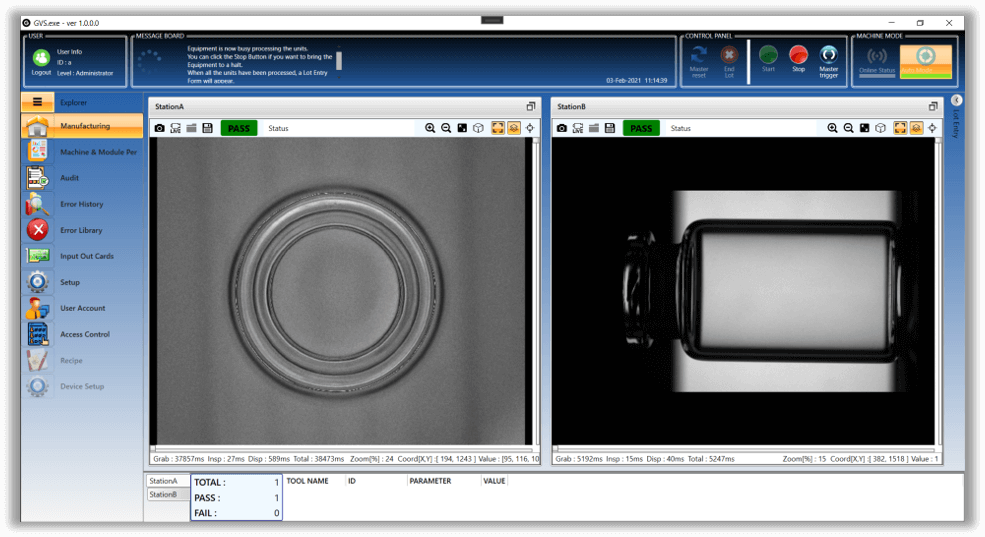

The company is also focusing on the efficiency of its infrastructure, which could be achieved by systematic machinery upgrades, process optimisation and implementation of smart monitoring technologies to cut waste.

“Achieving further reductions will come from two areas: doubling down on these efficiency gains to ensure our intensity continues to fall and scaling our share of RE well beyond the current 10%,” she says.