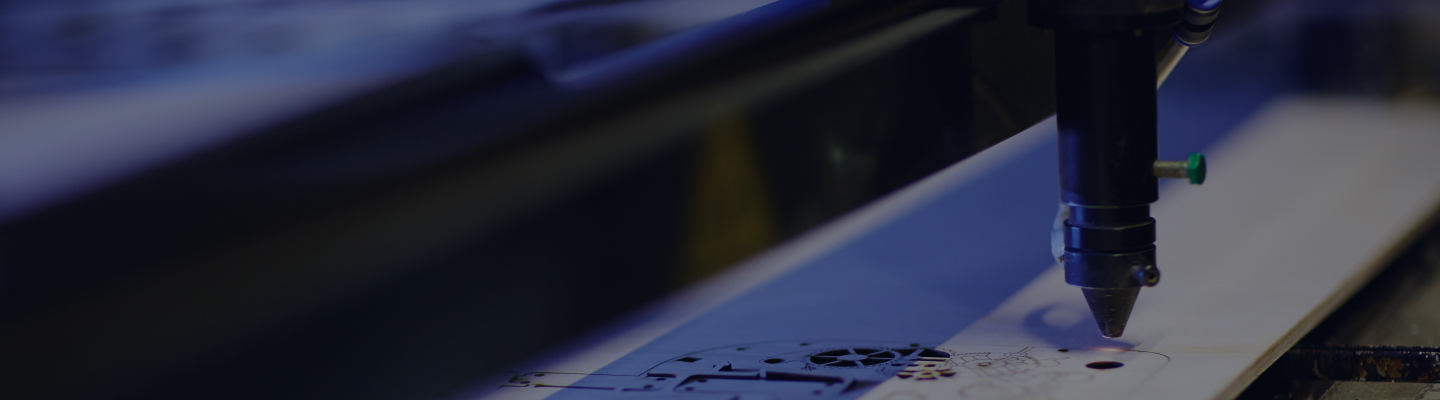

Laser

We design and integrate high precision modules such as Laser, Optical Engine, Vision and Robotic Arms.

Our strategic partnerships with laser suppliers and automation design gives the customer state-of-the-art laser processing tools in precision motion, advanced automation and material handling.

We are providing customized solutions to client needs to fit the requirement and our laser processing technology covers the process for drilling, ablation, micro-machining, cutting and marking.

Our Standard Industrial Laser Platform:

- Mechanical frame for stabilized motion

- High precision motion controls

- Class 1 laser safety enclosure

- Ergonomic user interface with touchscreen

- Easy access for routine maintenance

- Powerful turn-key software solution

- High throughput and Costs saving

- Solution without compromising quality

LS-500 Model

- A stand-alone full Gantry XYZ System to carry the Optical Engine to perform laser ablation process. A special custom Optical Engine design in approximate 765mm²/sec in 10m/sec scan speed.

- Dual Chucks design reduces the laser idle time and maximizes the production throughput. One chuck with panel in laser processing while the other chuck in panel exchanging process.

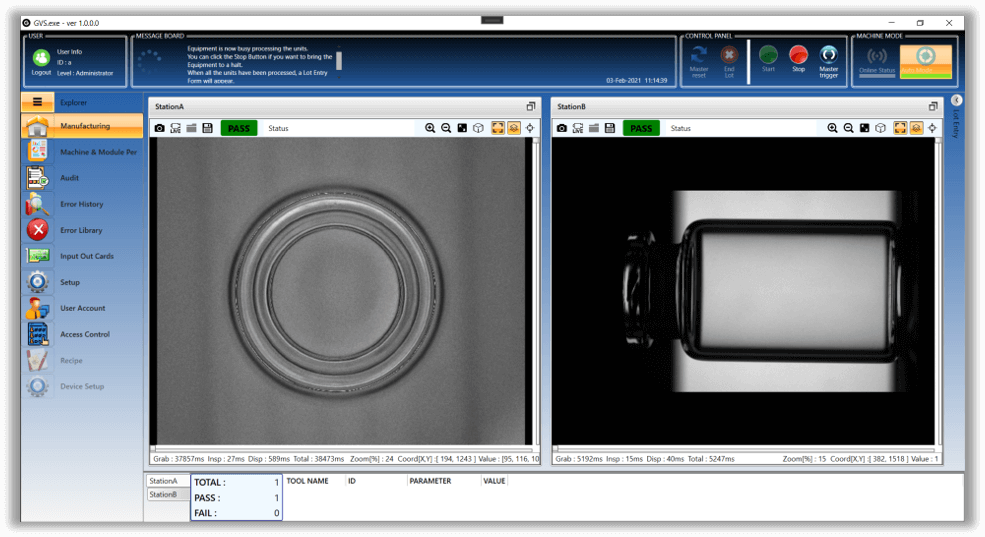

- Embedded with a high accuracy vision system for panel alignment and process positioning.

- Software CAD/CAM engine with precision motion controls, supporting DXF and DWG file formats.

- System is ready to integrate with production line system in custom conveyor and pick-and-place design.

- Class 1 laser safety enclosure.

- Ergonomic user interface with touchscreen.

LS-520 Model

- A stand-alone Decoupler XYZ System to carry the Optical Engine to perform laser ablation process. A special custom Optical Engine design in trimming and cavity drill processing at different materials.

- Dual Chucks design reduces the laser idle time and maximize the production throughput. One chuck with panel in laser processing while the other chuck in panel exchanging process.

- Embedded with high accuracy vision system for panel alignment and process positioning.

- Software CAD/CAM engine with precision motion controls, supporting dxf and dwg file formats.

- System is ready to integrate with production line system in custom conveyor and pick-and-place module design

- Class 1 laser safety enclosure

- Ergonomic user interface with touchscreen

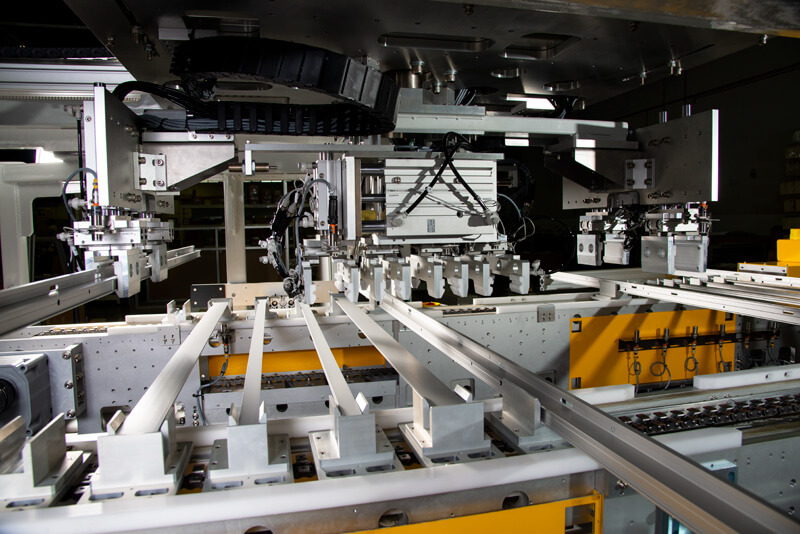

LS-530 & LS-540 Model

- A full automated Gantry System design to carry the Optical Engine to perform laser welding in battery busbar and sensor weld.

- Built-in conveyor system in soft dock with upstream and downstream machine for battery transporting and empty pallet returning. Reduce human handling and maximize production throughput

- A high accuracy vision system for panel alignment and process positioning.

- A friendly and powerful turn-key software solution for system setup and operation.

- Class 1 laser safety enclosure

- Ergonomic user interface with touchscreen