Internet of Things

Digital transformation, collecting data from machines, help to analyze these raw data to useful information for different level of user based on their needs.

Greatech Industrial Internet of Thing (IoT) Dashboard helps manufacturing to do digital transformation, collecting data from machines, help to analyze these raw data to useful information for different level of user based on their needs.

By leveraging Operation Technology (OT), Information Technology (IT) and Communication Technology (CT), User know in real time what is happening in the production line, can response faster for problem, reduce downtime and maximize production output hence improve the production cost.

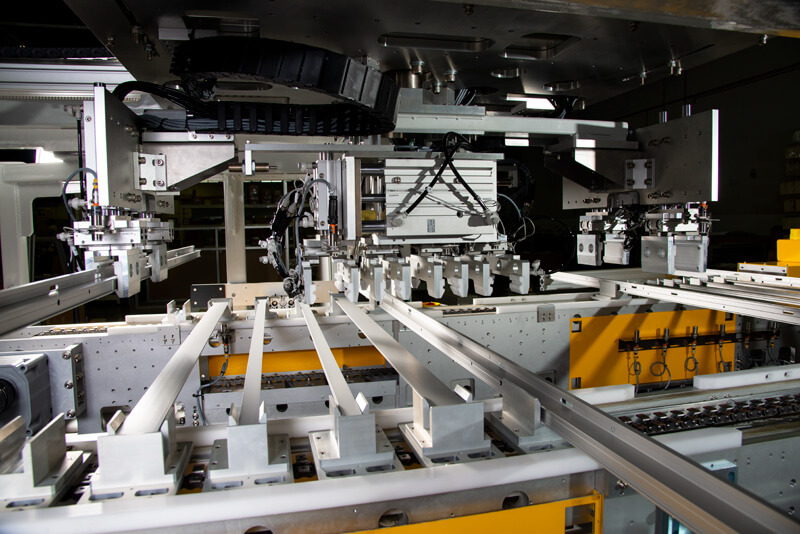

Machine Visibility:

Achieved by capturing real time data from the machine.

Flexible Connects Machines on Production Lines:

Communicate with various types of Operational Technology/System/Machine (Programmable Logic Controller – PLC, PC Based, Microcontroller Based, Various IO Bus, Supervisory Control and Data Acquisition – SCADA)

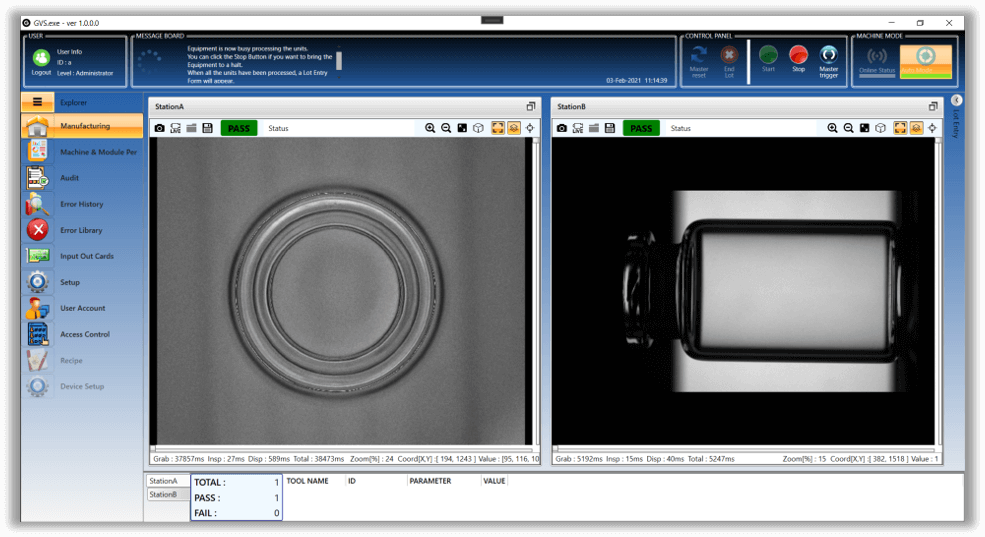

Machine OEE:

OEE – Overall Equipment Effectiveness is the key operational metric for machine uptime and capacity utilization that helps factory manager to monitor the performance of a particular machine, machine across lines or production floor machines. These parameters can be calculated out based on data capturing from machines.

Continuous Improvement:

With OEE figure, we will drill down machine process to increase machine utilization, increase production/operational efficiency, decrease product cost and improve product quality based on data.